Purpose

This article explores different options available for various types of emergency generator applications. The applications discussed include generators exposed to weather and generators located inside of a facility.

• Permanent enclosed generator – Complete generator system housed in an enclosure that is located on gravel or concrete pad.

• Portable enclosed generator – Generator system housed in an enclosure that is mounted on a trailer frame. Commonly used in construction sites. Easiest to complete initial setup on because unit is self-sufficient.

• Generators located inside of a facility – Often can have redundant backup. Facility generators can be fueled by natural gas or diesel fuel. Day tanks are common in diesel fuel applications.

Permanent Enclosed Generator

Site Planning

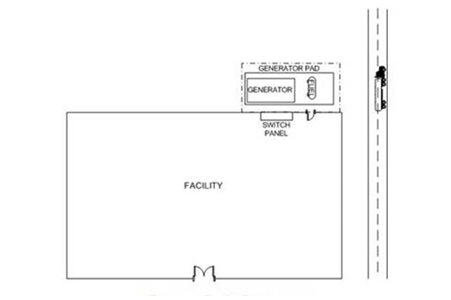

When setting up the site always use the generator manufacturer, state and federal guidelines. It is helpful to design a basic drawing of the generator and supporting systems Some considerations to be made are:

• Generator located with enough clearance between building and fuel supply to allow major maintenance.

• Fuel supply located accessible to fuel truck.

• Security fence installation for safety purposes.

• Buried or above ground fuel and electrical services.

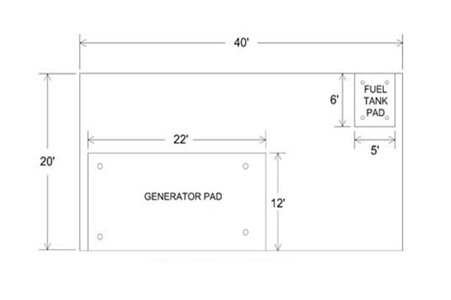

The generator area can be designed to be large enough to fit the fuel tank and allow for major maintenance to be completed with ease. A Caterpillar 1000 kW generator set was used in the creation of the generator area. The following statistics were used in calculations:

• Physical size of generator (21 ½’ x 11 ½’).

• Weight of generator with fuel tanks full (44,000 lbs.).

• Fuel consumption of generator (71 gal per hour full load).

• Back up fuel supply tank (600 gallon).

Always consult local, state and federal regulations when designing the generator area. Spill containment should be considered. Fuel stored between back up fuel tank and generator fuel tank is 1200 gallon. This allows for 16 hours of continuous operation at full load.

Concrete Pad Design

It is not advised and against many building codes to place a generator set on gravel. The generator must be kept level and vibrates during operation and must be secured to a permanent structure. Concrete is the industry standard for normal soil applications.

The thickness and size of the pad is controlled by soil composition among many other geographical considerations. Consult all federal, state, and local authorities when determining the following:

• Ambient temperature for concrete pour (quick setting or normal). Fresh pours must be utilize vibration to insure all air bubbles are dissipated.

• Weight concrete can withstand (heavy loads require reinforcement).

• Amount of pad protrusion past generator set (overall size plus ½”). Accurate measurements must be acquired when calculating.

Concrete Anchors

Securing the generator set and backup fuel supply tank is usually completed using concrete anchors There are many options for anchoring equipment to concrete:

• Heavy Duty Anchor – Installed prior to concrete pour. Taking good mounting measurements imperative.

• Adhesive Bond – Concrete cured, hole drilled, epoxy and stud installed. Stud must be square and level.

• Mechanical Bond – Concrete cured, hole drilled, stud set and tightened. Minimum requirements.

Portable Enclosed Generator

Portable generators require less site preparation than any other style of generator. They are offered in a variety of sizes from the Caterpillar 320 kW to the Baldor 2000 kW. Often portable generators are used in construction site applications supplying main power.

Site Preparation

One advantage of using a portable generator is that it can be moved to different locations at the same job site for power requirements as the job progress. A Baldor 2000 kW generator is required to satisfy power requirements on a construction site. Preparing the site for the arrival of the generator can include the following:

• Road established to location(s) of generator.

• If generator moves locations on site, area prepped prior to move.

• Generator dimensions are 46’ x 9’ with a height of 13’. Appropriate clearance to get to lot and size of lot able to support generator.

• Generator weight is 67,000 lbs. If soil conditions are moist, dunnage can be used under rear wheels for support.

• Fuel usage for engine under full load is 142 gallons per hour, with a 2800 gallon fuel tank allowing for 19.72 hours of operation.

• Support lifting gear with dunnage prior to engaging to remove from truck.

Generators Located Inside Facility

Generators that are purchased to be located inside a facility are most commonly a self-contained system . The engine, generator and engine cooling system are placed on a skid and factory aligned for operation. When moving the generator into the facility consider the following:

• Clearance – Enough for generator to be moved and placed onto concrete pad.

• Facility lifting device – Construction fork truck, installed overhead crane system or portable gantry system.

• Unload from truck – Construction fork truck or crane. Place in prep area to ready to be located in facility.

Site Preparation

Preparing a facility for a generator set installation has a few additional steps. Setting up generator set mounting and auxiliary systems prior to installation can save system down time. Always consult federal, state and local authorities for regulations prior to beginning site preparation. The below items can be performed prior to setting the generator set:

• Concrete pad – Located appropriate distance to allow for generator maintenance. Concrete to regulations.

• Generator skid mounts – Number and location of mounts depends on size and style. Attach mounts to pads (must be aligned and square) to concrete pad.

• Intake air – Engine intake air is supplied from air in the room. Must have positive air supply when engine(s) are operating.

• Fuel supply – Some regulations require fuel supply piping to be located under floor level and protected by grating.

• Electrical drops – Have drops ready to run after installation.

• Cooling air – Ductwork with louvers can be installed so the generator set can be attached to them prior to removal of lifting device.

• Exhaust – Building must have exhaust system installed for the generator. The building exhaust can be installed prior to installing generator set.

|